1. Upset Forging

Upset forging increases the diameter of the workpiece by compressing its length. Based on number of pieces produced this is the most widely used forging process. A few examples of common parts produced using the upset forging process are engine valves, couplings, bolts, screws, and other fasteners. Upset forging is usually done in special high-speed machines called crank presses, but upsetting can also be done in a vertical crank press or a hydraulic press. The machines are usually set up to work in the horizontal plane, to facilitate the quick exchange of workpieces from one station to the next. The initial workpiece is usually wire or rod, but some machines can accept bars up to 25 cm (9.8 in) in diameter and a capacity of over 1000 tons. The standard upsetting machine employs split dies that contain multiple cavities. The dies open enough to allow the workpiece to move from one cavity to the next; the dies then close and the heading tool, or ram, then moves longitudinally against the bar, upsetting it into the cavity. If all of the cavities are utilized on every cycle then a finished part will be produced with every cycle, which makes this process advantageous for mass production.

http://www.kt-forge.co.uk/upset-forging

2. Sheffield eCommerce

Professional and creative web design services. We build web sites for businesses across South Yorkshire, Rotherham, Sheffield, Doncaster and Barnsley. From a simple brochure to e-commerce with advanced dynamic content features, we can build the web site t promote your business on-line.

http://www.1t-s.com/internet-web-design

3. Rotherham eCommerce

Professional and creative web design services. We build web sites for businesses across South Yorkshire, Rotherham, Sheffield, Doncaster and Barnsley. From a simple brochure to e-commerce with advanced dynamic content features, we can build the web site t promote your business on-line.

http://www.1t-s.com/internet-web-design

4. Sheffield Custom Software

Custom software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://sheffield.custom.software.1t-s.com

5. IT Services

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://www.1t-s.com/service

6. Barnsley Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.barnsley.bespoke.software.1t-s.com

7. House For Rent Huddersfield

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://www.iam4rent.co.uk/house-for-rent-huddersfield

8. Cooper Split Bearings

A Cooper Split Bearing, also known as a Cooper Roller Bearing or simply a Cooper Bearing, is a type of rolling-element bearing designed with a split housing, allowing for easy installation, inspection, and maintenance. The Cooper Split Bearing is particularly useful in applications where it would be challenging or time-consuming to disassemble the entire bearing housing to access the bearing components. These bearings are known for their durability, flexibility, and ease of maintenance.

https://bearingswebshop.com/categories/cooper-split-bearings

9. Drop Forging

Drop forging is a metal shaping process, the metal to be formed is first heated then shaped by forcing it into the contours of a die, this force can be in excess of 2000 tons. The drop forging process can be performed with the material at various temperatures. Hot Forging: During hot forging the metals are heated to above their recrystallization temperature. The main benefit of this hot forging is that work hardening is prevented due to the recrystallization of the metal as it begins to cool. Cold Forging: Cold Forging is generally performed with metal at room temperature below the the recrystallization temperature. Cold forging typically work hardens the metal. There are two types of drop forging, open die and closed die. Open die drop forging requires the operator to position the work piece while it is impacted by the ram. The die attached to the ram is usually flat or of a simple contour, most of the shaping is achieved by the operator physically positioning the work piece before each stroke of the ram. There are also special dies which can be used to cut the metal, form holes or notches.

http://www.kt-forge.co.uk/drop-forging

10. 304 Stainless Steel

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com

11. Barnsley Linux

1T Solutions install and support linux based open source solutions and systems to small and medium businesses across Rotherham, Sheffield, Barnsley, Doncaster, Chesterfield and across South Yorkshire.

http://barnsley.linux.1t-s.com

12. Low Pressure Fittings

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com

13. Open Die Forging

Open-die forging is also known as smith forging. In open-die forging, a hammer strikes and deforms the workpiece, which is placed on a stationary anvil. Open-die forging gets its name from the fact that the dies (the surfaces that are in contact with the workpiece) do not enclose the workpiece, allowing it to flow except where contacted by the dies. Therefore the operator needs to orient and position the workpiece to get the desired shape. The dies are usually flat in shape, but some have a specially shaped surface for specialized operations. For example, a die may have a round, concave, or convex surface or be a tool to form holes or be a cut-off tool. Open-die forging lends itself to short runs and is appropriate for art smithing and custom work. In some cases, open-die forging may be employed to rough-shape ingots to prepare them for subsequent operations. Open-die forging may also orient the grain to increase strength in the required direction. Cogging is successive deformation of a bar along its length using an open-die drop forge. It is commonly used to work a piece of raw material to the proper thickness.

http://open-die-forging.kt-forge.co.uk

14. Stainless Steel Low Pressure Fittings

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/low-pressure-fittings/3

15. Student Accomodation Huddersfield

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://www.iam4rent.co.uk/student-accomodation-huddersfield

16. Threadolets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/high-pressure-fittings/4?&Fitting=Threadolet

17. Sheffield Custom Software

Custom software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.sheffield.custom.software.abrt.com

18. Sheffield Application Development

Computer applications software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://sheffield.application.development.abrt.com

19. Computer Services

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://www.1t-s.com/computer-services

20. Stainless Steel Gaskets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com

21. Stainless Steel

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com

22. Computer Maintenance

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://1t-s.com/computer-maintenance

23. Waste Collection Software

Skip Manager has been designed to enable you to manage the hire of your skips more effectively. From the initial bookings, hire, tracking and collections to credit control, Skip Manager has the functionality required for your Waste Recycling business.

http://waste-collection-software.skip-manager.com

24. Sheffield Application Development

Computer applications software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.sheffield.application-development.1tsolutions.com

25. South Yorkshire Computer Services

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://south-yorkshire.computer.service.1t-s.com

26. Application Development

Computer applications software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.application.development.abrt.com

27. Doncaster Open Source

1T Solutions install and support linux based open source solutions and systems to small and medium businesses across Rotherham, Sheffield, Barnsley, Doncaster, Chesterfield and across South Yorkshire.

http://www.doncaster.open-source.1t-s.com

28. Cold Forging

Cold forging is a high speed manufacturing process whereby metal is shaped at room temperature often without the need for the removal of material. A simple blank is placed within a die and a punch is pressed into the blank. The blank then takes on the form of the punch and the die. By utilising multiple dies and punches in succession very complex shapes can be achieved. Metal is forced beyond its yield (elastic) limit and retains its altered shape upon removal from the die. The metal is not forced beyond its tensile strength, otherwise fracturing would occur (the exception is when trimming or piercing). Historically cold forming has been an experienced based technology, but this is changing as new computer based analytical tools are constantly being developed.

http://www.ktforge.co.uk/cold-forging

29. Doncaster Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://doncaster.bespoke-software.1tsolutions.com

30. Waste Collection System

Skip Manager has been designed to enable you to manage the hire of your skips more effectively. From the initial bookings, hire, tracking and collections to credit control, Skip Manager has the functionality required for your Waste Recycling business.

http://www.waste-collection-system.skip-manager.co.uk

31. Sheffield Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://sheffield.bespoke-software.1tsolutions.com

32. Hammer Forging

The most common type of forging equipment is the hammer and anvil. Principles behind the hammer and anvil are still used today in drop-hammer equipment. The principle behind the machine is simple: raise the hammer and drop it or propel it into the workpiece, which rests on the anvil. The main variations between drop-hammers are in the way the hammer is powered; the most common being air and steam hammers. Drop-hammers usually operate in a vertical position. The main reason for this is excess energy (energy that isn't used to deform the workpiece) that isn't released as heat or sound needs to be transmitted to the foundation. Moreover, a large machine base is needed to absorb the impacts. To overcome some shortcomings of the drop-hammer, the counterblow machine or impactor is used. In a counterblow machine both the hammer and anvil move and the workpiece is held between them. Here excess energy becomes recoil. This allows the machine to work horizontally and have a smaller base. Other advantages include less noise, heat and vibration. It also produces a distinctly different flow pattern. Both of these machines can be used for open-die or closed-die forging. A forging press, often just called a press, is used for press forging.

http://hammer-forging.ktforge.co.uk

33. Stainless Steel Butt-Weld Fittings

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/butt-weld-fittings/2

34. Student Accomodation Huddersfield

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://www.iam4share.co.uk/

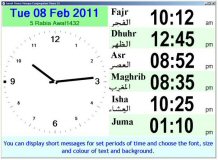

35. Salat Timings

Salat Timings, Clock, Islamic calendar and message display board software program for PCs designed specially for Masjids and Mosques. Suitable for Jamat Times, Salah Timetable, Namaz Times, Salaat Times. Free Download.

http://salat-timings.jamat-times.com

36. Huddersfield University Student Accomodation

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://huddersfield-university-student-accomodation.iam4rent.co.uk/

37. Open Die Forging

Open-die forging is also known as smith forging. In open-die forging, a hammer strikes and deforms the workpiece, which is placed on a stationary anvil. Open-die forging gets its name from the fact that the dies (the surfaces that are in contact with the workpiece) do not enclose the workpiece, allowing it to flow except where contacted by the dies. Therefore the operator needs to orient and position the workpiece to get the desired shape. The dies are usually flat in shape, but some have a specially shaped surface for specialized operations. For example, a die may have a round, concave, or convex surface or be a tool to form holes or be a cut-off tool. Open-die forging lends itself to short runs and is appropriate for art smithing and custom work. In some cases, open-die forging may be employed to rough-shape ingots to prepare them for subsequent operations. Open-die forging may also orient the grain to increase strength in the required direction. Cogging is successive deformation of a bar along its length using an open-die drop forge. It is commonly used to work a piece of raw material to the proper thickness.

http://www.ktforge.co.uk/open-die-forging

38. Stainless Steel Fittings

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com

39. Swaging

T=Swaging is a forging process in which the dimensions of an item are altered using a die or dies, into which the item is forced. Swaging is usually a cold working process; however, it is sometimes done as a hot working process. Virtually all metals that can be moulded / drawn out may be forged by first heating and then hammering it in to the desired shape. A billet, wrought bar, cast or sintered ingot etc.. may be forged. Forging improves the toughness and strength of improving orientation of the metal grain structure. The repeated heating and hammering causes the metal to become more dense and the grain "flow lines" to follow the contour of the end product.

http://swaging.ktforge.co.uk

40. ZX55.com

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

http://www.zx55.com

41. Chesterfield Custom Software

Custom software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://chesterfield.custom-software.1tsolutions.com

42. Barnsley Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.barnsley.bespoke-software.1tsolutions.com

43. Custom Software

Custom software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://custom.software.abrt.com

44. Smith Forging

Forging worked between flat or simple contour dies by repeated strokes and manipulation of the workpiece. Also known as "hand" or "flat die " forging.Heavy workpieces could be processed using a smith-forging hammer, and smaller forgings are die formed in drop hammers. Smith forging hammers are typically steam or air-operated, consisting of a power actuated ram supported by a heavy cast iron frame. The final product is a result of the ram being powered into the dies containing the workpiece.

http://www.ktforge.co.uk/smith-forging

45. Stainless Steel Flange Gaskets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/gaskets/8

46. Computer Services

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://www.abrt.com/computer-services

47. Hammer Forging

The most common type of forging equipment is the hammer and anvil. Principles behind the hammer and anvil are still used today in drop-hammer equipment. The principle behind the machine is simple: raise the hammer and drop it or propel it into the workpiece, which rests on the anvil. The main variations between drop-hammers are in the way the hammer is powered; the most common being air and steam hammers. Drop-hammers usually operate in a vertical position. The main reason for this is excess energy (energy that isn't used to deform the workpiece) that isn't released as heat or sound needs to be transmitted to the foundation. Moreover, a large machine base is needed to absorb the impacts. To overcome some shortcomings of the drop-hammer, the counterblow machine or impactor is used. In a counterblow machine both the hammer and anvil move and the workpiece is held between them. Here excess energy becomes recoil. This allows the machine to work horizontally and have a smaller base. Other advantages include less noise, heat and vibration. It also produces a distinctly different flow pattern. Both of these machines can be used for open-die or closed-die forging. A forging press, often just called a press, is used for press forging.

http://hammer-forging.kt-forge.co.uk

48. Stainless Steel Gaskets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/gaskets/8

49. Stainless Steel Forging

Virtually all metals that can be moulded / drawn out may be forged by first heating and then hammering it in to the desired shape. A billet, wrought bar, cast or sintered ingot etc.. may be forged. Forging improves the toughness and strength of improving orientation of the metal grain structure. The repeated heating and hammering causes the metal to become more dense and the grain "flow lines" to follow the contour of the end product.

http://stainless-steel-forging.kt-forge.co.uk

50. Email Spam Filter

A spam filtering service suitable for small and medium businesses, the 1T Solutions Gatekeeper service is competitively priced, and removes over 95% of e-mail spam and viruses.

http://www.1t-s.com/spam-filter

51. Doncaster Linux

1T Solutions install and support linux based open source solutions and systems to small and medium businesses across Rotherham, Sheffield, Barnsley, Doncaster, Chesterfield and across South Yorkshire.

http://www.doncaster.linux.1t-s.com

52. Custom Software

Custom software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.abrt.com/custom-software

53. Chesterfield Custom Software

Custom software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.chesterfield.custom-software.1tsolutions.com

54. High Pressure Fittings

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/high-pressure-fittings/4

55. Rotherham Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.rotherham.bespoke-software.1tsolutions.com

56. Stainless Pipe Supplier

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

http://www.zx55.com

57. Stainless Steel Valves

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/valves/7

58. Weldolets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/high-pressure-fittings/4?&Fitting=Weldolet

59. Student Accomodation Huddersfield

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://www.iam4share.co.uk/

60. Stainless Steel Flange Gaskets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/gaskets/8

61. Stainless Steel Tubing

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/pipes/6

62. Student Accomodation in Huddersfield

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://student-accomodation-huddersfield.iam4share.co.uk/

63. Chesterfield Software Development

Software Development, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.chesterfield.software.development.abrt.com

64. Waste Collection Software

Skip Manager has been designed to enable you to manage the hire of your skips more effectively. From the initial bookings, hire, tracking and collections to credit control, Skip Manager has the functionality required for your Waste Recycling business.

http://waste-collection-software.skip-manager.co.uk

65. South Yorkshire eCommerce

Professional and creative web design services. We build web sites for businesses across South Yorkshire, Rotherham, Sheffield, Doncaster and Barnsley. From a simple brochure to e-commerce with advanced dynamic content features, we can build the web site t promote your business on-line.

http://www.1t-s.com/internet-web-design

66. Computer Services

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://abrt.com/computer-services

67. Doncaster eCommerce

Professional and creative web design services. We build web sites for businesses across South Yorkshire, Rotherham, Sheffield, Doncaster and Barnsley. From a simple brochure to e-commerce with advanced dynamic content features, we can build the web site t promote your business on-line.

http://www.1t-s.com/internet-web-design

68. Doncaster Software Development

Software Development, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://doncaster.software.development.1tsolutions.com

69. Sheffield Web Design

Professional and creative web design services. We build web sites for businesses across South Yorkshire, Rotherham, Sheffield, Doncaster and Barnsley. From a simple brochure to e-commerce with advanced dynamic content features, we can build the web site t promote your business on-line.

http://sheffield.web-design.1t-s.com

70. Threadolets

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com

71. Barnsley Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://barnsley.bespoke.software.abrt.com

72. Chesterfield Application Development

Computer applications software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://chesterfield.application-development.1tsolutions.com

73. High Pressure Fittings

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/high-pressure-fittings/4

74. SKF Bearings

Steel City Bearings are one of the worlds leading suppliers of all bearing and transmission products. Steel City Bearings Ltd can offer the following to all its customers: Massive stocks of all leading brands * Same day despatch on ALL stock items * Over 100 years of bearing and transmission knowledge * Highly competitive pricing * Friendly and reliable sales team * Over 25,000 lines and 250,000 items in stock * Next day delivery to mainland UK including Northern Ireland

http://www.steelcitybearings.com

75. Cold Forging

Cold forging is a high speed manufacturing process whereby metal is shaped at room temperature often without the need for the removal of material. A simple blank is placed within a die and a punch is pressed into the blank. The blank then takes on the form of the punch and the die. By utilising multiple dies and punches in succession very complex shapes can be achieved. Metal is forced beyond its yield (elastic) limit and retains its altered shape upon removal from the die. The metal is not forced beyond its tensile strength, otherwise fracturing would occur (the exception is when trimming or piercing). Historically cold forming has been an experienced based technology, but this is changing as new computer based analytical tools are constantly being developed.

http://cold-forging.ktforge.co.uk

76. Student Diggs in Huddersfield

4 Bedroom house to share: Student accomodation available to rent near Huddersfield University. House with four bedrooms to let with common sitting-room, shared kitchen and batchroom with over the bath shower. Two of the rooms have on suite toilet and wash basin. The house is located in the Paddock area of Huddersfield, post code HD1 and is 1.4 miles from the University, 1.2 miles from the Huddersfield train station. The house is on a regular bus route, buses 301a, 302 (every 15 minutes) and 302a.

http://student-diggs-huddersfield.iam4share.co.uk/

77. Steel Forging

Virtually all metals that can be moulded / drawn out may be forged by first heating and then hammering it in to the desired shape. A billet, wrought bar, cast or sintered ingot etc.. may be forged. Forging improves the toughness and strength of improving orientation of the metal grain structure. The repeated heating and hammering causes the metal to become more dense and the grain "flow lines" to follow the contour of the end product.

http://steel-forging.ktforge.co.uk

78. Chesterfield Software Development

Software Development, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://chesterfield.software.devlopment.1t-s.com

79. Rotherham Software Development

Software Development, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://www.rotherham.software.development.1tsolutions.com

80. Rotherham Application Development

Computer applications software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://rotherham.application-development.1tsolutions.com

81. Computer Support

Computer service and support across Rotherham, Sheffield, Doncaster and Barnsley. 1T Solutions Ltd offer cost effective computer maintenance for small and medium businesses.

http://www.computer.support.1t-s.com

82. Hot Forming

Hot forging is the plastic deformation of metal at a temperature and strain rate such that recrystallization occurs simultaneously with deformation, thus avoiding strain hardening. For this to occur, high workpiece temperature (matching the metal's recrystallization temperature) must be attained throughout the process. A form of hot forging is isothermal forging, where materials and dies are heated to the same temperature. In nearly all cases, isothermal forging is conducted on superalloys in a vacuum or highly controlled atmosphere to prevent oxidation.

http://www.kt-forge.co.uk/hot-forming

83. Open Die Forging

Open-die forging is also known as smith forging. In open-die forging, a hammer strikes and deforms the workpiece, which is placed on a stationary anvil. Open-die forging gets its name from the fact that the dies (the surfaces that are in contact with the workpiece) do not enclose the workpiece, allowing it to flow except where contacted by the dies. Therefore the operator needs to orient and position the workpiece to get the desired shape. The dies are usually flat in shape, but some have a specially shaped surface for specialized operations. For example, a die may have a round, concave, or convex surface or be a tool to form holes or be a cut-off tool. Open-die forging lends itself to short runs and is appropriate for art smithing and custom work. In some cases, open-die forging may be employed to rough-shape ingots to prepare them for subsequent operations. Open-die forging may also orient the grain to increase strength in the required direction. Cogging is successive deformation of a bar along its length using an open-die drop forge. It is commonly used to work a piece of raw material to the proper thickness.

http://www.kt-forge.co.uk/open-die-forging

84. Barnsley Bespoke Software

Bespoke software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://barnsley.bespoke.software.1t-s.com

85. Press Forging

Press forging works by slowly applying a continuous pressure or force, which differs from the near-instantaneous impact of drop-hammer forging. The amount of time the dies are in contact with the workpiece is measured in seconds (as compared to the milliseconds of drop-hammer forges). The press forging operation can be done either cold or hot. The main advantage of press forging, as compared to drop-hammer forging, is its ability to deform the complete workpiece. Drop-hammer forging usually only deforms the surfaces of the workpiece in contact with the hammer and anvil; the interior of the workpiece will stay relatively undeformed. Another advantage to the process includes the knowledge of the new part's strain rate. We specifically know what kind of strain can be put on the part, because the compression rate of the press forging operation is controlled.

http://www.kt-forge.co.uk/press-forging

86. Stainless Steel Pipes

ZX55.com are on-line suppliers of stainless steel products including Butt-Weld Fittings, Flanges, Gaskets, High Pressure Fittings, Hygenic Fittings, Low Pressure Fittings, Pipes and Valves.

https://www.zx55.com/product-list/pipes/6

87. Rotherham Application Development

Computer applications software, tailored to your business practices. 1T Solutions have been delivering bespoke integrated systems since our inception in 2001. The underlying philosophy with all our bespoke software projects is to wrap the software around our clients' business. It is a very sad fact, even today, that many software houses develop applications where the client must change their business practices to suit the software - not so with 1T Solutions. From small businesses to corporate clients, across a wide industry spectrum, we have a wealth of expertise in designing and implementing diverse business solutions.

http://rotherham.application.development.1t-s.com

88. Skip Hire System

Skip Manager has been designed to enable you to manage the hire of your skips more effectively. From the initial bookings, hire, tracking and collections to credit control, Skip Manager has the functionality required for your Waste Recycling business.

http://www.skip-hire-software.skip-manager.com

Rotherham Web Design - Sheffield Application Development - Barnsley Application Development - Barnsley Application Development - Stainless Steel Butt-Weld Fittings - Barnsley Bespoke Software

Huddersfield University Accomodation - Huddersfield University Accomodation - Bespoke Software - Contact Management Software - Barnsley Bespoke Software - Roll Forging

Smith Forging - Rooms For Rent Huddersfield - Barnsley Computer Services - Chesterfield Application Development - Custom Software - Computer Maintenance

Forging Steel - Press Forging - Barnsley Software Development - Stainless Steel Gaskets - Software Development - Student Accomodation in Huddersfield

Stainless Steel Low Pressure Fittings - Application Development - Skip Hire Software - Stainless Steel Hygienic Fittings - Student Accomodation Huddersfield - Waste Recycling System

Stainless Steel High Pressure Fittings - Computer Repair - Sheffield Linux - Cold Forging - Student Diggs in Huddersfield - Hygienic Fittings

Sockolets - Rooms For Rent Huddersfield - Stainless Steel Flanges - Surplus Bearings - Student Accomodation in Huddersfield - Application Development

Ball Bearings - South Yorkshire Open Source - Chesterfield Bespoke Software - Sanitary Fittings - Chesterfield Web Design - Stainless Steel Fittings

Doncaster Custom Software - Waste Management Software - Needle Roller Bearings - Chesterfield Application Development - Computer Support - Forging Steel

Application Development - Stainless Steel Forging - Ball Bearings - Rooms For Rent Huddersfield - Rooms For Rent Huddersfield - Computer Repair

Stainless Steel High Pressure Fittings - Chesterfield Software Development - Student Accomodation Huddersfield - Doncaster Custom Software - Skip Manager - Rooms For Rent Huddersfield

Skip Manager - Barnsley Software Development - Sheffield Web Design - Huddersfield University Student Accomodation - Waste Recycling System - South Yorkshire Software Development

Chesterfield Bespoke Software - Stainless Steel Hygienic Fittings - SKF Bearings - Doncaster Software Development - Open Die Forging - Hot Forging

Drop Forging - Computer Repair - Sheffield Custom Software - Custom Software - Sheffield Bespoke Software - Computer Services

Sheffield Bespoke Software - Chesterfield Bespoke Software - Software Development - Press Forging - Doncaster Open Source - Threadolets

Upset Forging - Rotherham Open Source - Student Diggs in Huddersfield - Waste Collection Software - Rotherham Custom Software - Domain WhoIs

Doncaster Application Development - Computer Repair - Engineering Blacksmiths - Stainless Steel Butt-Weld Fittings - Business Contact Manager - Gatekeeper

Stainless Steel - Butt-Weld Fittings - Computer Services - Huddersfield University Accomodation - South Yorkshire Bespoke Software - Skip Hire Software

Smith Forging - Butt-Weld Fittings - Accounts Software for Stockists - Chesterfield Custom Software - Software Development - South Yorkshire Software Development

Student Accomodation in Huddersfield - Rotherham Bespoke Software - 316 Stainless Steel - Free Accounts Software - Rotherham Custom Software - Doncaster Linux

Bespoke Software - Application Development - South Yorkshire Application Development - Chesterfield Linux - South Yorkshire Bespoke Software - Mosque Message Display Board

Swaging - Bespoke Software - Rotherham Bespoke Software - South Yorkshire Application Development - Stainless Steel Low Pressure Fittings - Stainless Steel Fittings

High Pressure Fittings - Application Development - Stainless Steel Hygienic Fittings - Bespoke Software - Rotherham Application Development - Skip Hire Software

Stainless Steel Flanges - South Yorkshire Open Source - South Yorkshire Bespoke Software - Computer Maintenance - Rooms For Rent Huddersfield - Rotherham Application Development

Drop Forging - Doncaster Bespoke Software - Doncaster Bespoke Software - Bankrupt Bearings - Computer Support - Application Development

Doncaster Software Development - Roll Forging - Bespoke Software - Sheffield Software Development - Huddersfield University Student Accomodation - Huddersfield University Student Accomodation

Sheffield eCommerce - Custom Software - Rotherham Software Development - House to Share Huddersfield - Bearings - Waste Collection System

Chesterfield Custom Software - Hammer Forging - Stainless Steel Low Pressure Fittings - Rotherham Custom Software - Stainless Steel Tubing - Hot Forging

Stainless Steel Tubing - Bulk Bearings - IT Services - Bespoke Software - South Yorkshire Custom Software - Custom Software

Student Diggs in Huddersfield - Stainless Pipe Supplier - Doncaster Application Development - Waste Recycling System - Stainless Steel Gaskets - Software Development

Stainless Pipe Supplier - Chesterfield Computer Services